-

Ash Eye

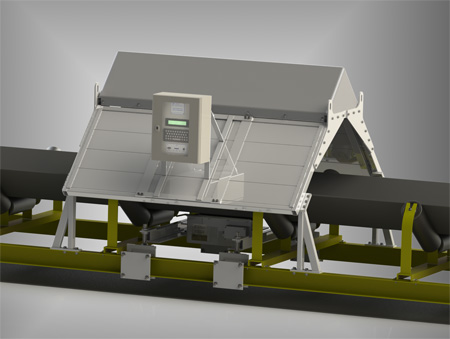

The Ash Eye is a coal quality monitoring system that attaches to conveyor belts to monitor the coal as it is moved from the mine to the stockpile or conveyor transportation, providing real time results of coal quality to the customer.

There are two types of Ash Eye:

The Standard Ash Eye

This is an Ash Sensor that is fully conveyor mounted. It has two 4-20mA outputs which can be configured for Instantaneous Ash, Instantaneous Tonnage Rate or Shift Accumulated Ash. It also has a Serial Output of all the measured and calculated parameters. These outputs can be fed to an existing computer control system for display, archive and analysis.The Full Ash Eye

The Full Ash Eye incorporates the EyeGraffix PC based Display/Archive/Retrieval system for use where the user has no SCADA computer monitoring system.Like all Bretby Gammatech products, Ash Eye uses Natural Gamma Technology, rather than radioactive sources, which means they are much safer and require no specialist de-commissioning equipment or procedures

Many of our customers find that the Ash Eye pays for itself in just a few weeks!

-

Ash Eye – benefits

- Highly effective means of identifying the source of dirty coal to enable managers to tackle the problem.

- Can be used to apportion coal products on the basis of ash content and tonnage

- In blending control systems, the use of Ash Eye information leads to a more consistent blend and higher financial rewards for the coal producer.

- In final product applications the Ash Eye has, in many cases, eliminated the requirement for hourly control samples – significant Heat Error improvements have been achieved – thereby reducing costs and increasing revenue to the user.

- Provides advance warning of problems e.g. changes in gravity levels, blocked chutes etc.

- In power stations, the Ash Eye is often used to identify dirty coal prior to it entering the boilers thus saving costly downtime and boiler cleaning.

-

How it works

The dirt associated with coal contains a higher concentration of radioactive material than the coal itself. The signal from a natural gamma detector mounted under the conveyor belt contains ash information. When this signal is combined with the mass of the material from a belt weigher, a measurement of the ash content can be obtained.

In order to counter the effects of changes in background radiation, signals from a small background sensor are also included in the ash calculation.

Accuracy

The accuracy of the Ash Eye depends upon the site and the belt weigher. Accuracies (1σ) of better than 0.5% ash on final product and 1-3% on run-of-mine have regularly been achieved. A precision of 0.5% ash can be achieved with final product systems (measured to ISO15239).

Ash Eye – features

- Simple, secure menu-driven operation, with automatic restart upon restoration of power.

- Real-time numerical displays of current ash content, the shift ash content, the current tonnes per hour flow rate and the total shift tonnes.

- Up to four calibrations to handle different coal types.

- Up to eight different coal types can be accommodated.

- User-definable shift pattern with comprehensive end-of-shift reporting.

- Archival and retrieval of shift reports.

- Two 4 to 20mA Analogue outputs which can be set to the current ash content, the shift ash content or the current tonnes per hour flow rate.

- Two Relay outputs (c/o contacts) which can be set to operate on a critical system fault, a non-critical system fault, the current ash content below a target band, within a target band or above a target band.

- User-definable quality parameters (target ash content and desired ash band).

- Downloading of information to Multi-Media-Card (MMC) or RS232 Serial port to allow more comprehensive user analysis (usually in conjunction with other user-supplied data).

- Optional serial output (RS232/RS485) of percentage ash, tonnage and various other house keeping data for onward transmission to the customer’s computer control system or the optional Bretby Gammatech EyeGraffix software system.

- Can be synchronised with the customer’s auto-sampler for dynamic calibration and/or for performance monitoring purposes.

Applications

- Run-of-Mine (ROM) Monitoring or Raw Coal Monitoring

- Control of diverting systems for high ash material

- Washed Coal - for input to washing plant control system

- Blending control systems

- Final product monitoring

- Monitoring Coal Deliveries at Power Plants, Steel Works & Cement Works

- Boiler feed monitoring

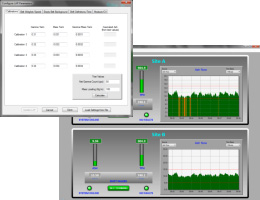

EyeGraffix Remote Monitoring Software

-

This is available with all Bretby Gammatech Ash-Eye products.