-

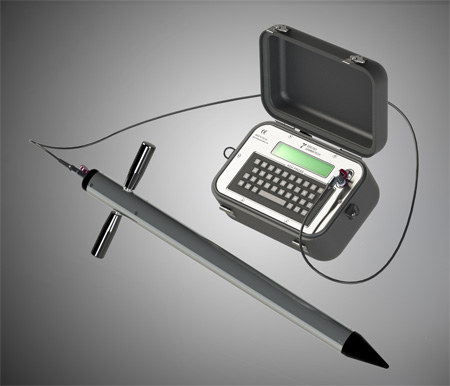

Ash Probe

The Ash Probe is a portable instrument for measuring the ash content of coal, providing the user with highly accurate readings within seconds. Instantaneous readings can be made of coal quality on stock piles, trains or trucks, allowing customers to check the quality of incoming coal supplies and specifications against their suppliers’ claims.

Widely used across the mining industry, it allows suppliers to verify the quality of their product and therefore have confidence that the delivery will be accepted by the client ensuring the agreed price per tonne is paid.

Ash-Probe was the first portable product to be developed by Bretby Gammatech, with the first one sold to a mine in South Wales. Since then, hundreds of Ash-Probes have been delivered all round the world, with many of these customers also purchasing Ash-Eye or Lab-Ash equipment too.

Like all Bretby Gammatech’s products, the Ash Probe uses natural gamma radiation, with no radioactive sources.

The Ash Probe has been developed to withstand harsh environments and is therefore renowned for being extremely robust. It is currently being used in temperatures down to -50°C in Mongolia, China, as well as in temperatures over 40°C in many African countries.

Ash Probe – benefits

- Much quicker than conventional sampling and analysis

- More information on Ash and Ash variability.

- Enables customer to blend more accurately - leading to a premium product

- Facilitates dispatch more quickly - reducing train standing time

- Enables increase of saleable tonnage - leading to increased revenue

- Reduces discard - leading to reduced disposal costs

- Reduces sampling effort - leading to reduced costs

- Coal buyers can reject inferior coal deliveries or negotiate lower prices

- Coal buyers can use information to blend deliveries

-

How to operate the Ash Probe

The Ash Probe comprises two main parts: a Probe and a Display Unit. To obtain an ash reading, the Probe is pushed into the coal pile or truck to be tested. After a few seconds an ash result shows on the Display Unit.

In order to obtain an accurate assessment of the ash content of the whole pile (or wagon load) the Probe is inserted at several locations. This is repeated until the desired precision level has been reached.

In Pile Mode up to 99 probings per pile can be made and data from up to 99 piles can be stored. In Truck Mode up to 12 probings per truck can be made and data from up to 600 trucks can be stored.

Calibration is readily achieved by the customer using the supplied calibration sample gathering equipment. The Display Unit can use up to 9 separate calibrations for different coal types.

Accuracy

Tests on a wide range of coals from over twenty countries on five continents have shown that the Ash Probe can measure the ash content to closer than 1% (1σ) ash. In some cases better than 0.5% (1σ) accuracy has been achieved with high grade anthracite.

Ash Probe – features

- Simple to use

- Handy portable format

- Accurate results within seconds (60-100 seconds depending upon ash content)

- Provides cumulative ashes from up to 99 measurements per pile (Pile Mode)

- Stores ash content of up to 99 piles (Pile Mode)

- Provides cumulative ashes from up to 12 measurements per truck (Truck Mode)

- Stores ash content for up to 600 trucks (Truck Mode)

- Easy to calibrate

- Can store up to 9 calibrations (in practice this number has never been needed)

- Fully downloadable data

- Rechargeable sealed lead acid battery gives over 20 hours continuous operation

- Optional serial printer available

- PC Based software application provided for data download and remote configuration

Applications

The Ash Probe is currently being used by customers around the world to provide quick testing for the ash content of:

- Run-of Mine (ROM) coal

- Washed product (smalls, peas, beans, singles, doubles etc.)

- Screened coal (dry fines, PSF etc.)

- Slurry

- Blended products

- Final Product (e.g. composite ash pile)

- Discard

- Unknown coals prior to blending

- Rail or truck deliveries to blending plants, power stations, coking plants and cement works