-

Heat Eye

The Heat Eye is a fully on-line instrument providing second-by-second measurement of the Ash, Moisture and Nett Calorific Value (Nett CV) ie the energy content of conveyed coal. This it produces in real-time rather than by the traditional method of laboratory analysis. This measurement is vital for decision making.

Heat Eye comprises an Ash Eye fully integrated with a moisture meter (e.g. Callidan MA500 or Berthold LB456 etc) The Heat Eye contains no Radioactive sources – it uses Natural Gamma and Microwave technology.

The new generation Heat Eye is fully modular. The basic Heat Eye is a conveyor mounted instrument providing real-time data to an existing computer control system. An optional Remote Display Unit is available for customers requiring a fully stand-alone system.

The Heat Eye is our latest development in world-class coal monitoring.

-

Heat Eye – benefits

- In blending control systems the good use of the Heat Eye information enables suppliers to produce a more consistent product leading to higher financial proceeds. For example, this can be achieved by adjusting the ash content to counter uncontrolled changes in moisture to provide a product with a consistent Nett CV.

- Enables a mine to adjust quickly and effectively the blend characteristics to meet the demands of customers requiring different Nett CV specifications.

- In power station applications the Heat Eye information can be used to ensure the boilers are fed with fuel with a Nett CV falling within specification. This will ensure maximum boiler efficiency. In extreme cases, Low CV material can be diverted from the boilers, thereby reducing downtime and the associated costs.

-

How it works

The Heat Eye combines the instantaneous ash and moisture measurements to obtain an instantaneous “total innerts” value. This total innerts value is converted into Nett CV by using a calibration based upon the correlation of total innerts with Nett CV previously measured by conventional means.

Accuracy

The accuracy of the Heat Eye will depend upon the site and the performance of each component sensor. Accuracies of (1 sigma) better than 0.5% on final product and between 1 and 3 % ash with run-of-mine (ROM) have been achieved with production systems.

Precisions in the order of 0.5% are regularly being achieved with final product monitors (Measured to ISO 15239)

Heat Eye – features

- Simple, secure menu-driven operation, with automatic restart upon restoration of power.

- Real-time numerical displays of current ash, moisture and CV along with current shift averages.

- Real-time numerical displays the current tonnes per hour flow rate and the total shift tonnes.

- Up to four calibrations to handle different coal types.

- Up to eight different coal types can be accommodated.

- User-definable shift pattern with comprehensive end-of-shift reporting.

- Archival and retrieval of shift reports.

- Two 4 to 20mA Analogue outputs which can be set to any two of the measured parameters.

- Two Relay outputs (c/o contacts) which can be set to operate on a critical system fault, a non-critical system fault, the current ash content below a target band, within a target band or above a target band.

- User-definable quality parameters (target ash & moisture content and desired ash & moisture band).

- Downloading of information to Multi-Media-Card (MMC) or RS232 Serial port to allow more comprehensive user analysis (usually in conjunction with other user-supplied data).

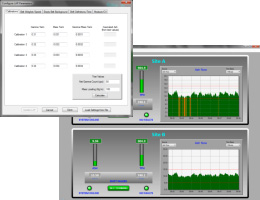

- Optional serial output (RS232) of the measured parameters and various other house keeping data for onward transmission to the customer’s computer control system or the optional Bretby Gammatech EyeGraffix remote monitoring softare system.

- Can be synchronised with the customer’s auto-sampler for dynamic calibration and/or for on-going performance monitoring.

Applications

- Run of mine (ROM) or raw coal monitoring

- Control of diverting system for out of specification material

- Washed coal – for input to washing plant control system

- In blending control system

- Final Product Monitoring

- Monitoring of coal deliveries at Power Stations, Coking Plants and Cement works

-

EyeGraffix Remote Monitoring Software

-

This is available with all Bretby Gammatech Ash-Eye products.